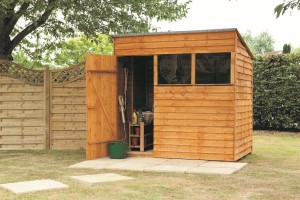

Sheds and Storage

Sheds with Windows |

||

|

Shed windows may function as fixed lights |

|

|

or open for added ventilation. | |

|

Sheds are normally supplied with perspex / acrylic windows. Mainly due to safety and security.

Is there a difference between perspex and acrylic? The answer is no, acrylic is the name of the material - perspex is just one particular brand name. There are many different manufacturers of acrylic.

|

|

|

|

||

Acrylic is: |

||

|

|

||

|

Impact resistant - Does not crack or break easily. |

|

|

Lightweight - Half the weight of glass alternatives. |

|

|

Durable - Any material exposed to the elements all year round has to be durable. Acrylic is used for signage and garden furniture. |

|

|

Weather resistant - Acrylic is extremely weather resistant, and is able to withstand low temperatures without cracking or becoming brittle. Because of this, it is often used in bus shelters. |

|

|

Transparent - Good quality acrylic is very clear and allows 92% of visible light to pass through it. It keeps its clarity without turning yellow when exposed to sunlight over long periods. |

|

|

Easy to work - Acrylic can be cut and drilled. | |

|

100% Recyclable - Perspex is recycled into recycling bins, so that what goes around, comes around. |

|

|

|

||

|

How do I clean perspex / acrylic?For general purpose cleaning, simply wash with clean cold water and a drop of washing-up liquid. The use of any solvents, e.g. white spirit or turpentine, is neither necessary nor recommended. |

|

|

Do perspex / acrylic sheets turn yellow in the sun?No, theyshould not turn yellow in the sun. Most manufacturers offer a 10 year guarantee against discolouration. |

|

|

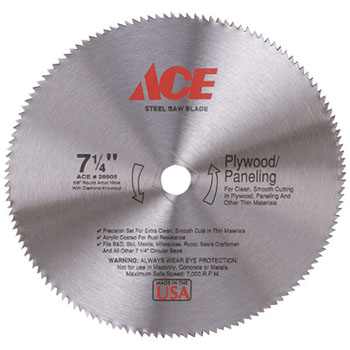

What tools can be used on perspex / acrylic sheets? To achieve a good finish, all tools used to cut acrylic need to be sharp. Jigsaws, handsaws, hacksaws and fret saws are all suitable for use on acrylic. When drilling holes in acrylic, use an electric drill with high speed steel bits. |

|

|

What is recommended when drilling holes in perspex / acrylic sheets? Use a small diameter drill bit to pilot the hole, followed by the correct diameter drill bit - drilling very slowly. The area you are drilling should be supported by a piece of wood to prevent cracking the exit hole. A countersink bit can then be used to clean the hole and to prevent cracking forming around the hole.

|

|

|

What types of saw are recommended?There are saws designed for cutting plastic, but fine-toothed saws for small jobs can be used, such as hacksaws and fret saws. The perspex / acrylic must be firmly fixed and only light pressure applied. |

|

Fitting Perspex / Acrylic Glazing to Your Shed Window |

||

|

|

||

|

Most manufacturers will supply a shed with the window(s) already glazed. |

|

|

If not, or at some stage you may need to replace existing glass or perspex / acrylic. |

|

|

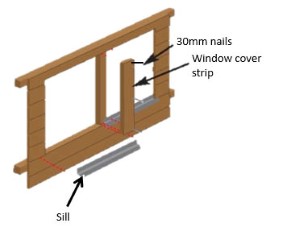

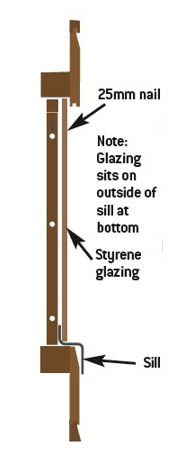

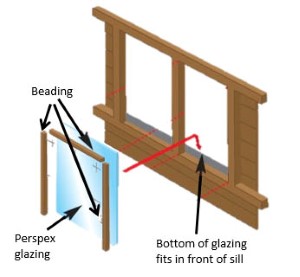

From the outside, place the sill [plastic 'z' strip] across the bottom of the window opening. The long face of the 'z' should face down the outside of the window side. Fix in place with 20mm panel pins. If a double window, put the cover strip in position and nail to the verticle frame. |

|

|

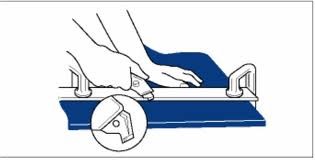

Place the glazing sheet into the window rebate from inside your shed. Make sure the bottom edge of the glazing sheet sits on the outside of the sill. |

|

|

From inside the shed, fix the window beading [top and sides only] with 25mm nails. The hammer will slide against the glazing sheet as you drive home the nail. |

|